Huge day at Backflow Direct...the USC One Year Field Clock started today on the following valves:

|

Friday, December 19, 2014

USC One Year Field Clock Starts for 2 1/2" - 3" (20/30)

Tuesday, November 25, 2014

Mori Seiki SH-500 Horizontal Machining Center Aquired

| The Big Blue Santa showed up again today and dropped off a new to us Mori Seiki SH-500 Horizontal Machining center. This machine will produce the 6" and 8" stainless steel bodies for the Deringer Product Line. |

|

Tuesday, November 11, 2014

All USC Field Sites for the 3" Deringer 20/30 Horizontal and Vertical Orientations Completed

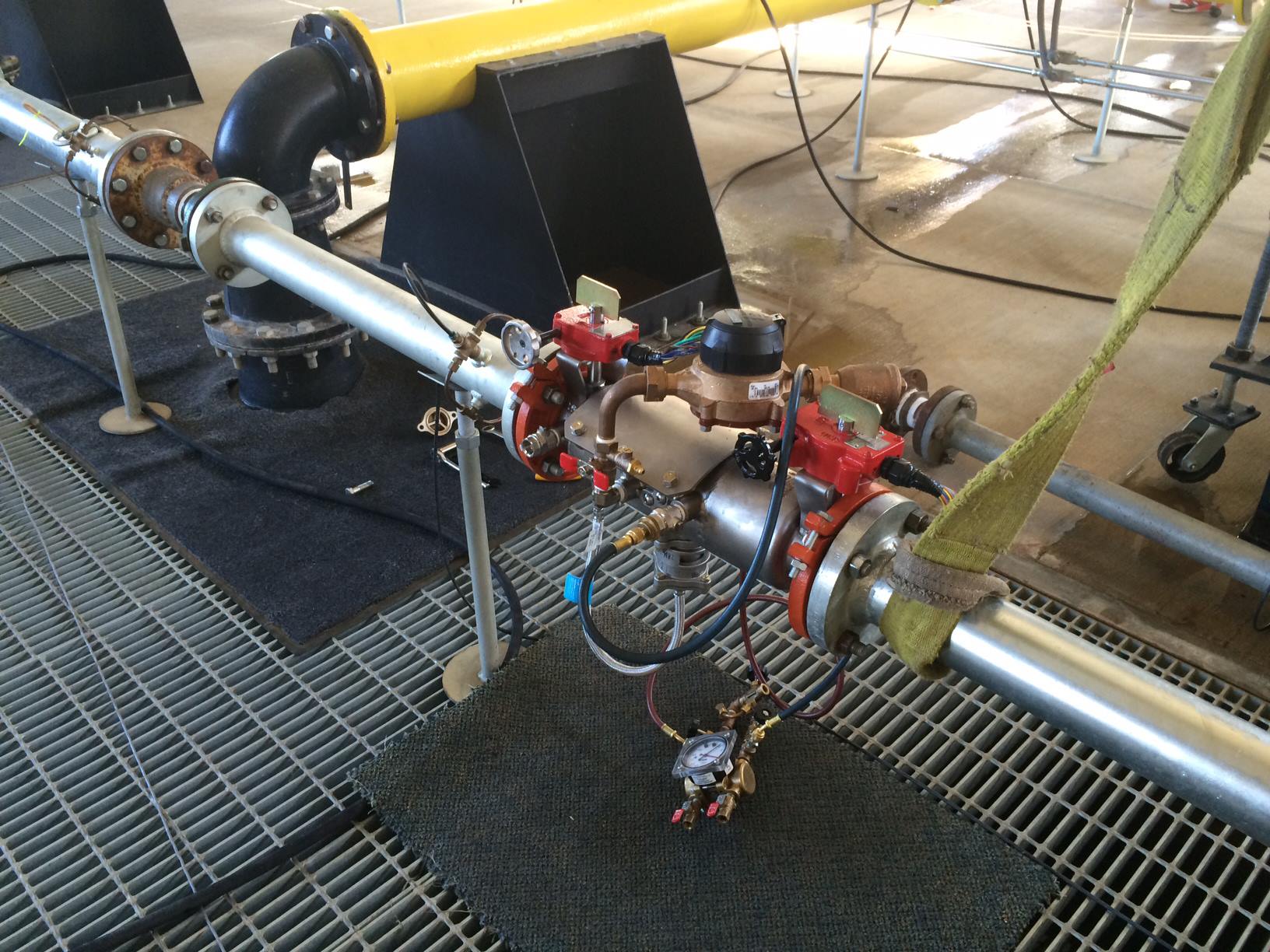

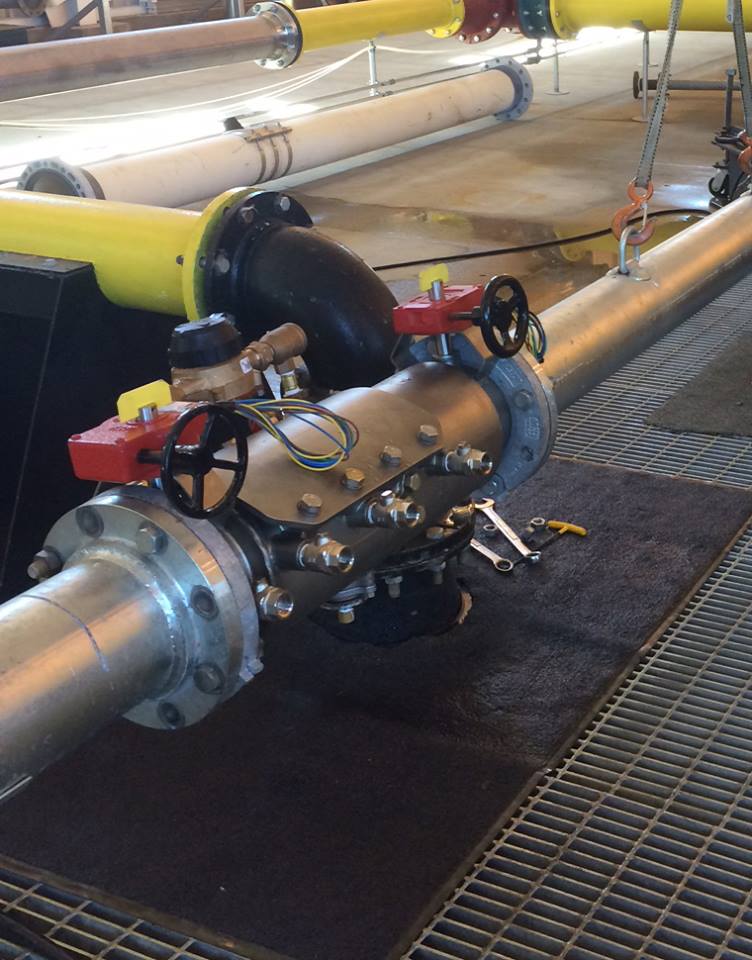

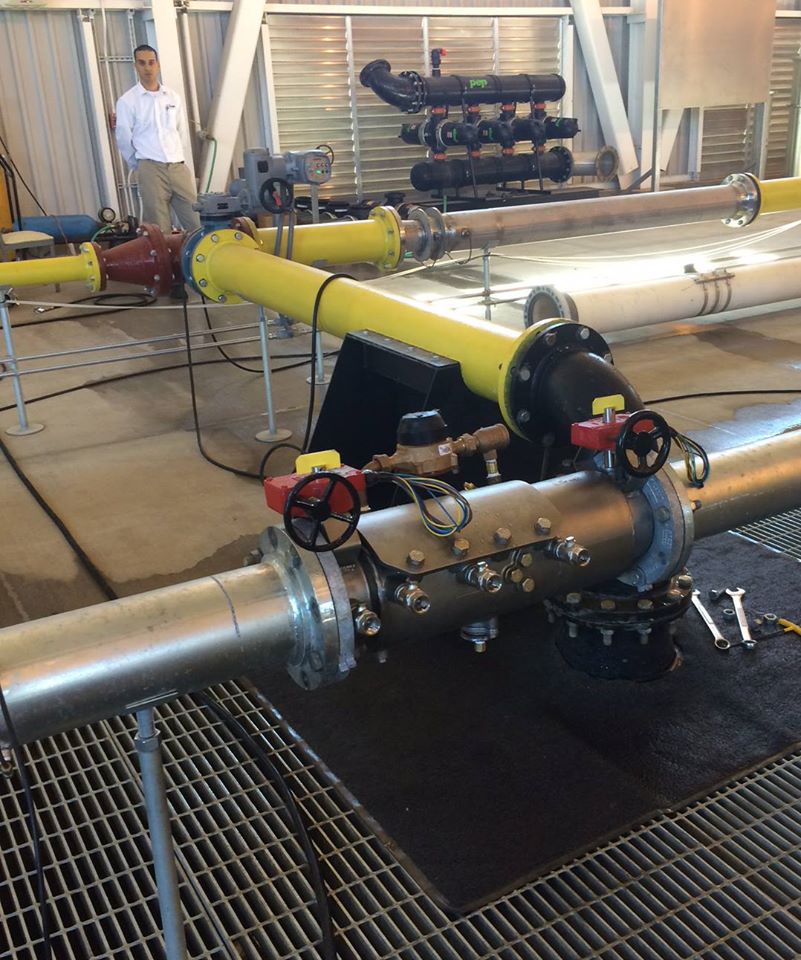

The installation of all USC field sites for the 3" Deringer 20/30 Horizontal and Vertical orientations was completed today. The blue and red valve on the ground required replacement due to complete corrosion failure. The stainless steel valve (top) is the Backflow Direct 3" Deringer 20. The two 6" black spools on both sides of the valve represent the length of the failed valve being replaced. This picture provides a great perspective of the size reduction of the Deringer Product Line verses the competition. |

|

Tuesday, October 28, 2014

ULC Classification for the complete line of Deringer Backflow Prevention Valves!

Today Backflow Direct received ULC Classification for the complete line of Deringer Backflow Prevention Valves. All ULC approved sizes, models and orientations are listed below:

To view the ULC online certification please click here FM and ASSE approvals will be announced in the very near future! |

UL Classification for the complete line of Deringer Backflow Prevention Valves

Today Backflow Direct received UL Classification for the complete line of Deringer Backflow Prevention Valves. All UL approved sizes, models and orientations are listed below:

To view the UL online certification please click here To our future customers, Backflow Direct is very close to introducing the backflow market to the world of online direct sales! |

Monday, October 27, 2014

UL Approval for all Butterfly Valves!

Today Backflow Direct received UL Listing for the complete line of SS705 Fire Prevention Butterfly Valve. All UL approved sizes and models listed below:

The paperwork for the FM approval of the SS705 should be complete shortly. |

Friday, October 10, 2014

UL, ULC and FM Testing Gallery

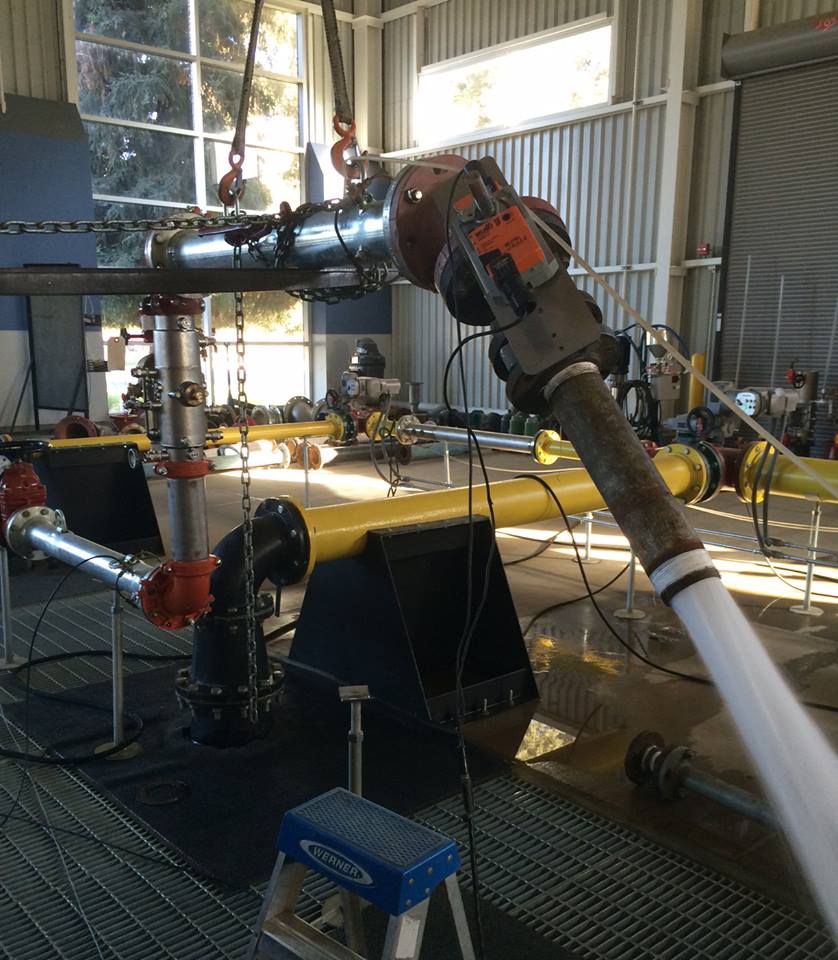

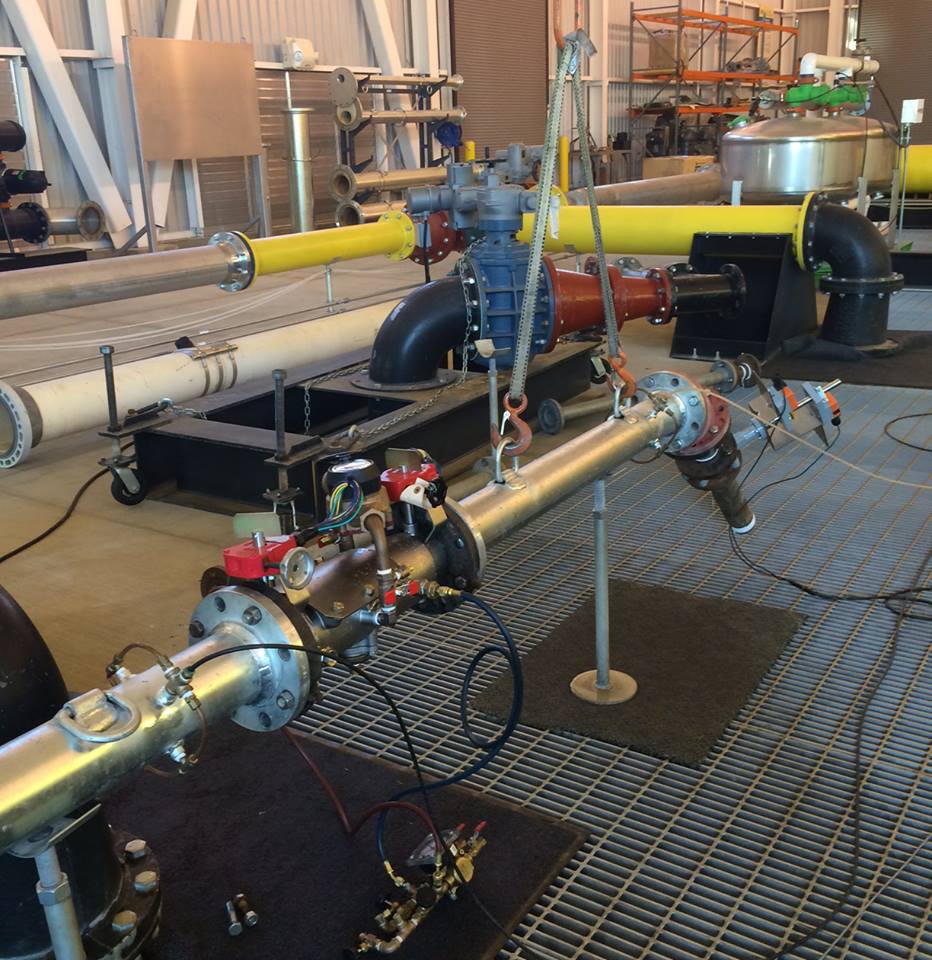

This is a gallery of pictures from the week of UL, ULC and FM testing at the CIT laboratory in Fresno. Almost all readers will find this gallery very boring, but we are certain that a few people will find this gallery very interesting. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Completed 100% of the product testing requirements for UL, ULC and FM for the entire Deringer backflow product line! In ONE WEEK!

How to properly represent the significance of this post was definitely a challenge. In a single week the Backflow Direct Team successfully completed 100% of the product testing requirements for UL, ULC and FM for the entire Deringer backflow product line. To our knowledge, no company in the backflow industry has ever accomplished such a feat. A recap of the week in a simple parody:

…because of the evolving nature of the backflow approval process, it is also very likely that such a feat will never be duplicated. Without a doubt this is the most significant accomplishment in the young life of this company. Lou and Matt your loyalty and hard work are greatly appreciated! Hunter (my son)…your participation in this adventure made it all the more special! |

|

| |

We have spent the last few weeks designing and building the vertical flow systems necessary to complete the UL and FM testing scheduled for next week. The lab testing on these systems was successful, pretty cool and really LOUD! |

|

| |

We would like to thank Suzanne Tosterud from Underwriters Laboratory (UL) for her dedication and energy during the preparation and arduous testing of Deringer product line. Her efforts relative to pre-test planning, fusing of UL and ULC standards, calibration certificate acquisition, days of tedious data recording, knowledge of standards and commitment to an orderly testing process were invaluable in the successful completion of this massive project. Thank you Suzanne!! We would like to thank Suzanne Tosterud from Underwriters Laboratory (UL) for her dedication and energy during the preparation and arduous testing of Deringer product line. Her efforts relative to pre-test planning, fusing of UL and ULC standards, calibration certificate acquisition, days of tedious data recording, knowledge of standards and commitment to an orderly testing process were invaluable in the successful completion of this massive project. Thank you Suzanne!! |

|

We would like to thank Chris Tolentino from Factory Mutual (FM) for his positive attitude and engineering perspective throughout the planning and testing of the Deringer product line. Chris’s commitment to completely understanding the engineering behind the Deringer product line, was critical in the elimination any redundant testing required by FM standards. His efforts helped create a very efficient and thorough testing schedule resulting in the successful completion of this likely unprecedented project. Thank you Chris!! |

|

Tuesday, September 30, 2014

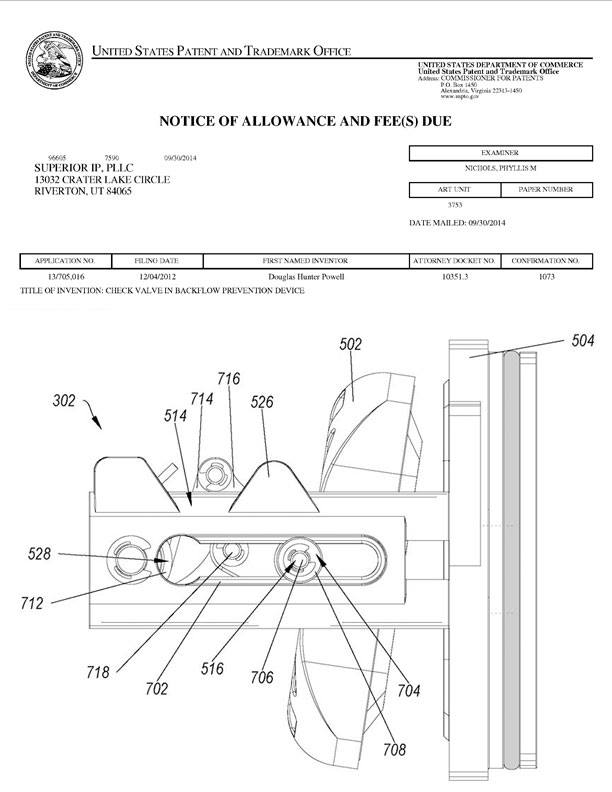

Dual-Action Check™ Module Patent

The Dual-Action Check™ Module is the cornerstone technology of the Deringer Product Line. Today the United States Patent & Trademark Office issued a "Notice of Allowance" to Backflow Direct for the Dual-Action Check™ Module (App #13/705,016). This Patent is expected to issue in the next 30 days. This is the third of four Patents associated with the proprietary protection of the Deringer Product Line. |

|

|

Monday, September 22, 2014

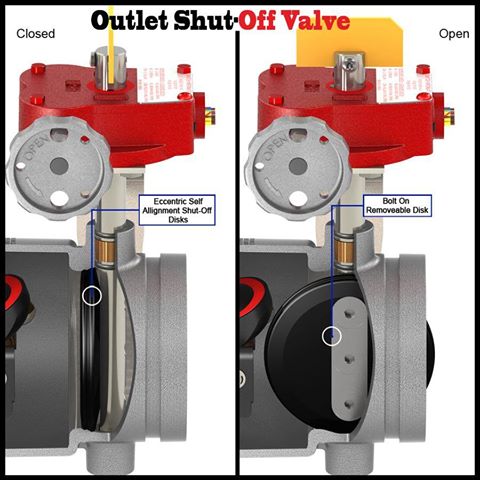

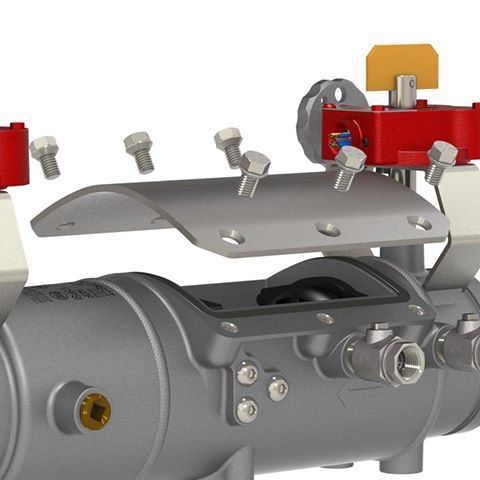

Patented Eccentric Seal Shut off Valve

Our Patented Eccentric Seal Shut off Valve utilizes an industry first single component actuation shaft that required the development of a safety key that could be controlled to break at a predetermined operational torque of the shutoff valve. Well the patent on this safety key has reached filed status. We know....it sounds like crazy geek speak! What does it really mean.... |

|

|

Tuesday, September 16, 2014

Vertical Orientation 1 Year USC Fieild Site Testing Starts Now!

We would like to thank the Staff of the USC FCCC Laboratory for spending the day with us finalizing all the testing necessary to START THE ONE YEAR USC FIELD TEST on the 4" Deringer 20/30 in the VERTICAL orientation. Once again this is another big milestone for our company...at this stage in our development CLOCK STARTS are the name of the game. |

|

Friday, September 5, 2014

100-ton CNC press break!

The Big Blue Santa from Lawson Drayage showed up today and delivered a 100-ton CNC press break! This press break will be used to form our patented stainless steel Bow-Seal Covers and the gear box mounting brackets for our Eccentric-Seal Shutoff Valves. |

|

Thursday, August 21, 2014

Vertical Orientation USC Life Cycle Test

This is a picture of the 4" Deringer 20/30 (Vertical Orientation) installed in the USC FCCC laboratory life cycle test. As of this post date the 4" Deringer 20/30 in the Vertical Orientation successfully completed all of the USC FCCC laboratory evaluation and has been released for the one year USC field evaluation. Another big milestone! |

|

Thursday, August 14, 2014

NCBPA Product Show and Workshop

Today, Backflow Direct participated in its first trade show the NCBPA Product Show and Workshop. It was a great event, with knowledgeable people and excellent food. We really appreciate all of the individuals that took the time to learn more about our product. As a small company we considered it an amazing day as 26 people chose to register with Backflow Direct to be future direct customers! Thank you! |

Friday, August 1, 2014

Fire Protection Butterfly Valve

These images are a draft Specification Sheet for the Backflow Direct SS705 line of fire protection butterfly valves. We successfully completed all UL testing and documentation process this week and are merely waiting for Listing verification. This is another big milestone for Backflow Direct in that the UL approval of our Backflow Product Line was first dependent upon UL approval of this butterfly product line. |

|

|

Thursday, July 24, 2014

THE CLOCK STARTS NOW! GAME ON!

We would like to thank the Staff of the USC FCCC Laboratory for spending the day with us finalizing all the testing necessary to START THE ONE YEAR USC FIELD TEST on the 4" Deringer 20/30. Those familiar with the arduous Backflow approval process will recognize this as a huge milestone for our company...CLOCK START...GAME ON! |

|

|

Eccentric-Seal™ Shutoff Valve Patent

It has been a good week at Backflow Direct, another Patent! Today the United States Patent & Trademark Office issued a "Notice of Allowance" to Backflow Direct for the Eccentric-Seal™ Shutoff Valve (App #13/705,033). This Patent is expected to issue in the next 30 days. This is the second of four Patents associated with the proprietary protection of the Deringer Product Line. |

|

| |

Friday, July 18, 2014

Bow-Seal™ Full Access Cover Patent

Today, the United States Patent & Trademark Office issued a "Notice of Allowance" to Backflow Direct for the Bow-Seal™ Full Access Cover (App #13/705,024). This Patent is expected to issue in the next 30 days. This is the first of four Patents associated with the proprietary protection of the Deringer Product Line. |

|

| |

Tuesday, June 24, 2014

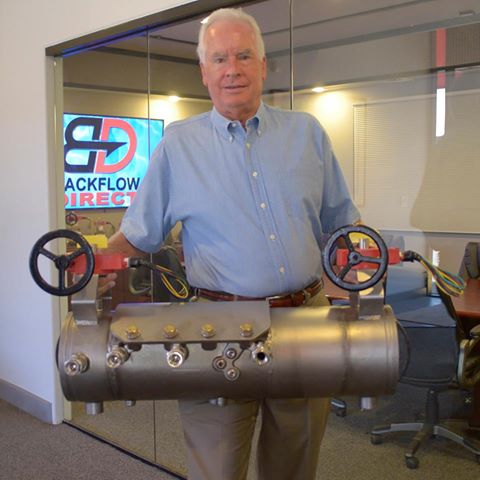

Shortest & Lightest Valve in the Industry

Kent Powell, CFO of Backflow Direct holding up our new 8" Double Check with built in stainless steel Shutoff Valves. Please don't try this with any of our competitors products!! The entire valve assembly weighs only 136lbs with an overall length of 30 3/4". By far...the shortest and lightest valve in the industry. |

|

|

Life Cycle Test

This is a picture of the 4" Deringer 20/30 (horizontal orientation) installed in the USC FCCC laboratory life cycle test. As of this post date the 4" Deringer 20/30 successfully completed all of the USC FCCC laboratory evaluation and is in the documentation process for release to the USC one year field evaluation. |

|

|

Friday, May 30, 2014

True Seal Check Modules

The first check valve in the Deringer 40/50 (RP & RPDA) products can be reconfigured to operate exactly like a traditional poppet. It was designed this way because the first check valve in an RP or RPDA backflow prevention valve provides the best flow performance when it operates like a traditional poppet style check valve. So not only are our check modules Dual-Action they are Dual Purpose. The True Seal Check Valve was designed to incorporate a poppet only motion during the check stroke and is used exclusively on the first check assembly on the Deringer RP and RPDA models. This design allows a more consistent pressure loss across the check valve which helps maintain a steady and continual closure of the Relief Valve.

|

|

This gif demonstrates the actuation of the first check valve in the Deringer 40/50 (RP & RPDA). Same components as the Dual-Action checks reconfigured to provide the best performance for an RP or RPDA. Features:

|

|

Thursday, May 8, 2014

Tamper Resistant Test Cocks

A new website graphic for the tamper resistant test cocks (ball valves) located on all Deringer products. The top of the valve actuation stem has a unique shape that uses an independent custom wrench to open/close the test cocks. |

|

|

Saturday, May 3, 2014

SS705 Butterfly Valve Product Line

The great thing about designing a backflow prevention device with "built in" stainless steel shut off valves is after the UL/FM approval process we end up with an additional product line for FREE. Introducing the Backflow Direct SS705 Line of Fire Protection Stainless Steel Shut-off Valves with pre-wired tamper switches. We believe the SS705 will be the first STAINLESS STEEL fire protection shut-off valve priced to compete directly with old antiquated CAST IRON butterfly valves. The SS705 should be available for direct purchase by fire sprinkler contractors by end of the year. Sizes pictured left to right: 2 1/2" - 3" - 4" - 6" - 8" |

|

|

Saturday, April 26, 2014

Deringer 30/50 Bypass Check Valve

Here are some new website graphics for the Deringer 30/50 Bypass Check Valve...all of whose features are fundamental to creating the smallest and lightest bypass assembly in the industry. The Deringer 30/50 Backflow Product lines use the same bypass assembly for all valve sizes 2 1/2" - 8". |

|

|

Friday, April 25, 2014

Starting USC Field Sites!

This is our Production Manager Matt Longo installing one of our USC field sites for the 4" Deringer 20/30 in the horizontal orientation. Normally one would not need a crane to install a 42lb valve however, we are replacing a competitors valve with a much longer lay length and had to add spools on both ends of our valve to make up for our short lay length. |

|

|

Thursday, April 10, 2014

Special Thanks to Badger Meter

We would like to extend a special thank you to Badger Meter for providing competitive volume pricing to BACKFLOW DIRECT in anticipation of our future success. |

|

|

Thursday, March 13, 2014

Backflow Direct Laser Marking System

The laser marking system for the 2 1/2" - 8" Deringer product line has been built, programmed, tooled and is fully functional. We are excited to see this up and running as this system was much more difficult to design than we originally anticipated. |

|

Monday, March 10, 2014

Utility Truck Acquisition

We got a great deal on this utility truck (w/ crane)! Having installed many USC field sites in the past, we know how valuable this vehicle will be in our future USC field site installations |

|

|

Thursday, March 6, 2014

Viking Automatic Stainless Steel Shot Blaster Acquisition

The Viking automatic stainless steel shot blaster has been rebuilt and is running great. We use this machine to produce a quality satin finish on all of our cast stainless steel valves. |

|

|

Monday, February 24, 2014

Mori-Seiki SH-400 Dual Pallet CNC Horizontal Machining Center Acquisition

The Mori-Seiki SH-400 Dual Pallet CNC Horizontal Machining Center has been installed and is currently being tooled for the drilling and tapping operations for the 2 1/2"-4" stainless steel valve housings as well as the boring operations for the 2 1/2"-4" stainless steel inlet and outlet shut-off valve housings. |

|

|