Aaron Colacchia joins the BACKFLOW DIRECT team as the Chief Operations Officer (COO) responsible for all business operations. |

|

Friday, December 7, 2012

Backflow Direct Chief Operations Officer

Backflow Direct Product Manager

Matt Longo joins the BACKFLOW DIRECT team as the PRODUCTION MANAGER responsible for the manufacture and quality control of the Deringer backflow prevention product line. |

|

Wednesday, December 5, 2012

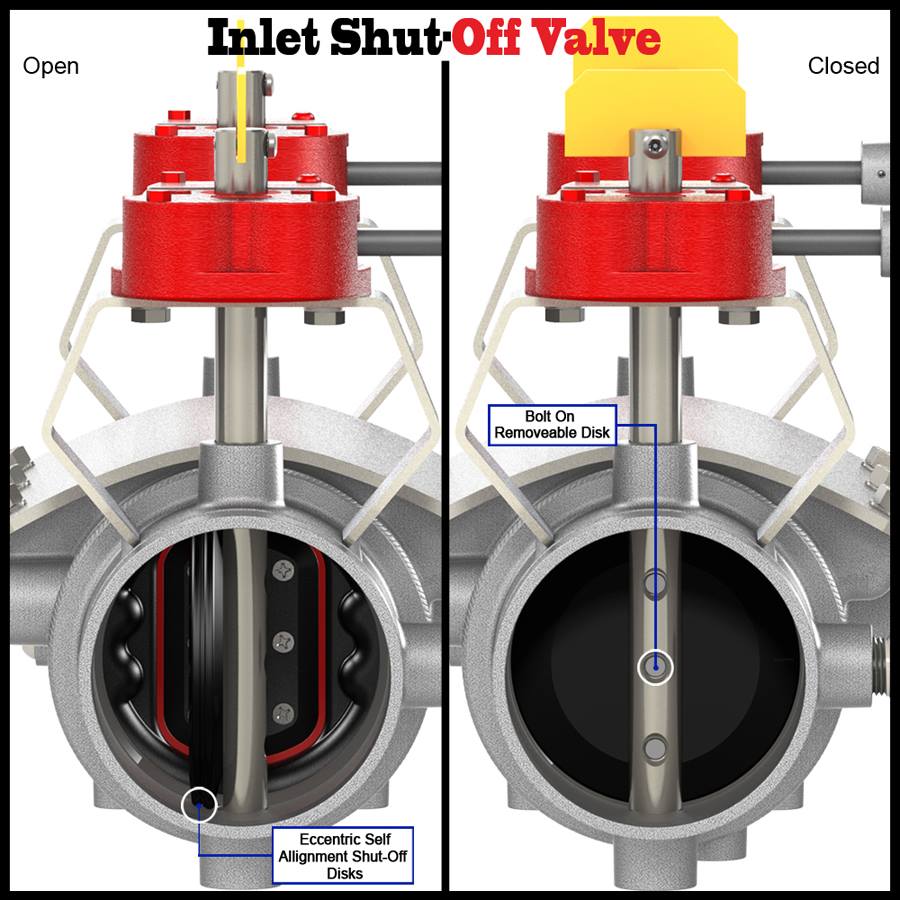

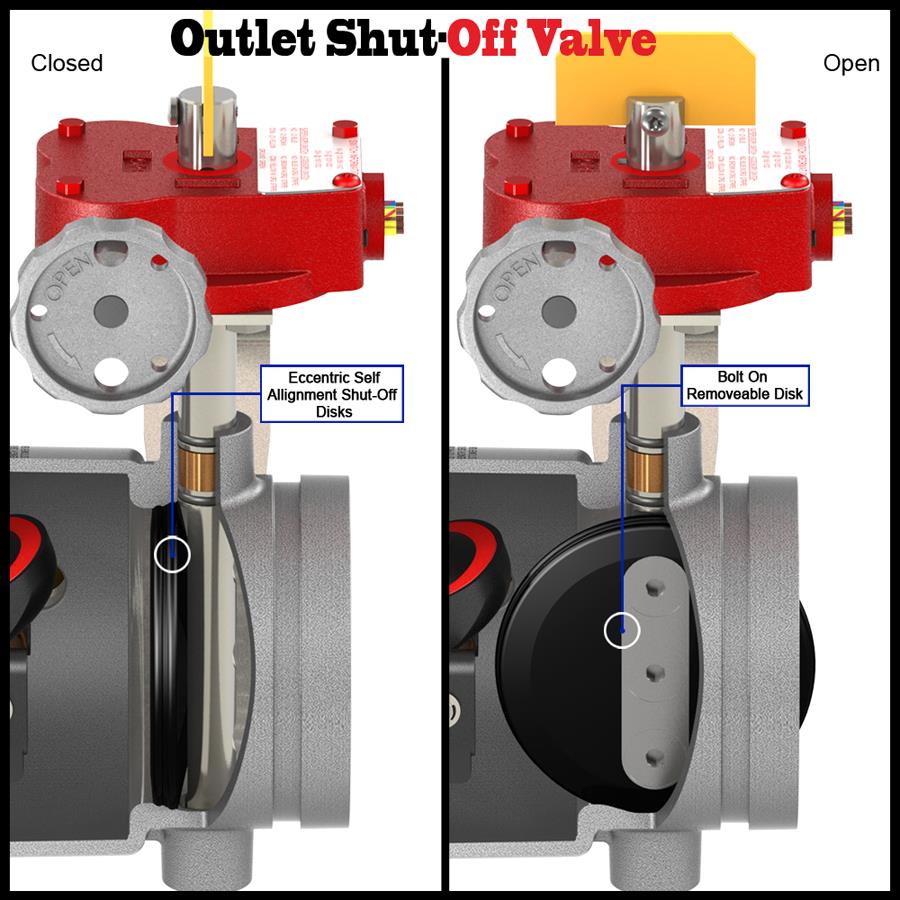

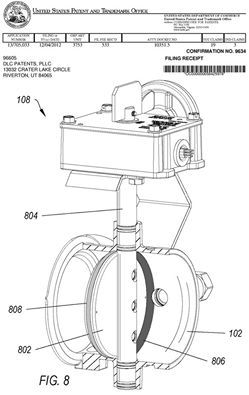

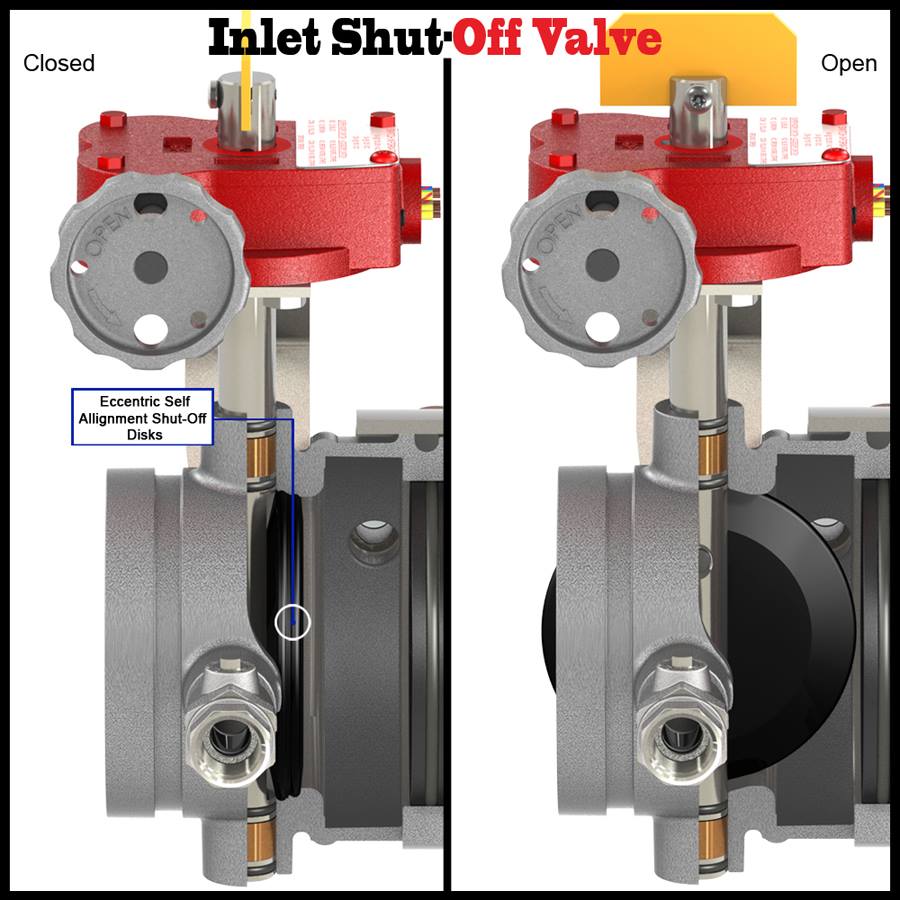

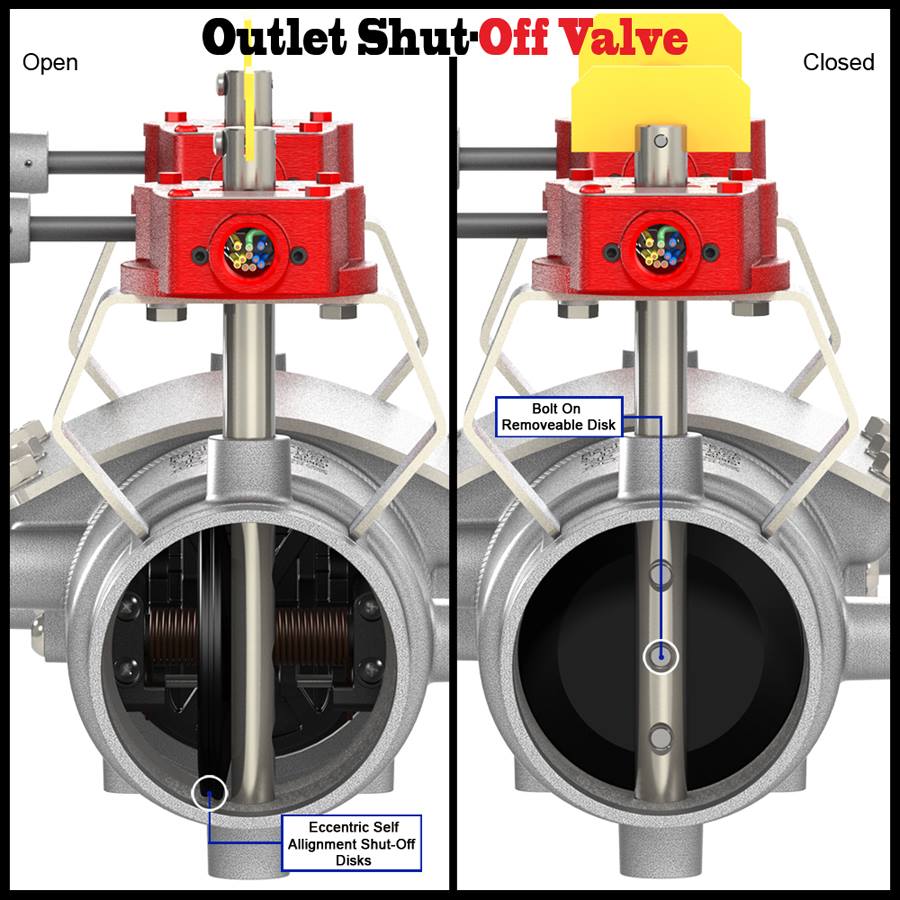

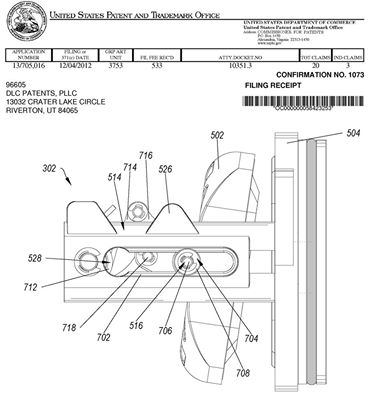

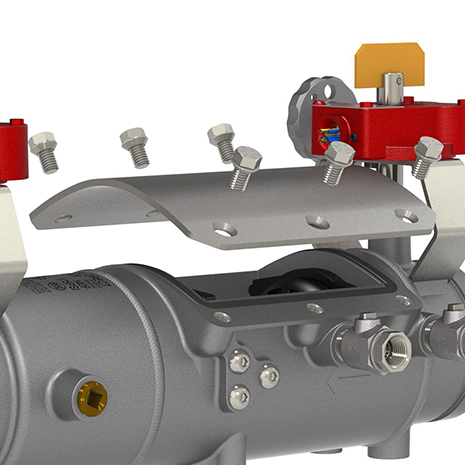

Eccentric-Seal Shutoff Valve US Patent Filing

| Backflow Direct filed for US Patent: Eccentric-Seal™ Shutoff Valve December 4, 2012 |  |

Eccentric Seal Shut-Off Valve

The only large diameter STAINLESS STEEL shutoff valves in the Backflow Industry. The Patent Pending Eccentric-Seal™ Shutoff Valve has a unique feature in that the inlet shutoff valve sealing disk seals on the downstream side of the valve operation shaft. This allows the #1 test cock to be located adjacent to the valve operation shaft reducing the overall length of the valve (and weight) by at least 2 inches. Additional features and benefits include:

|

|

|

|

|

|

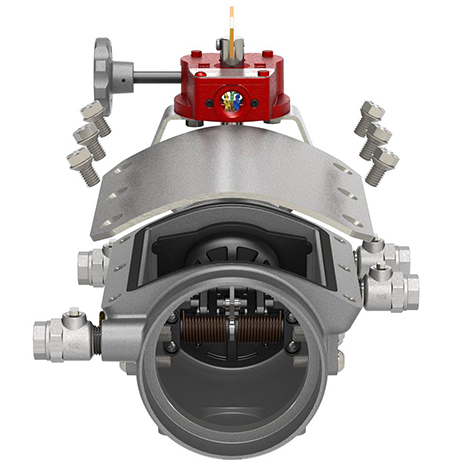

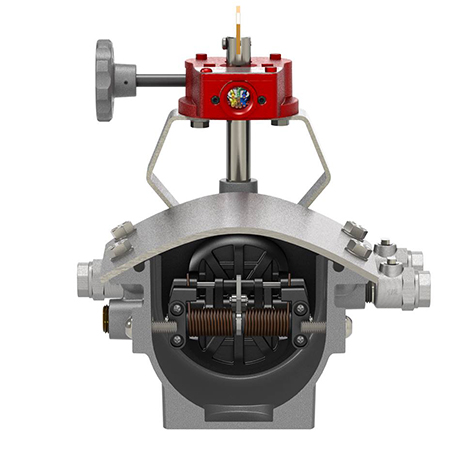

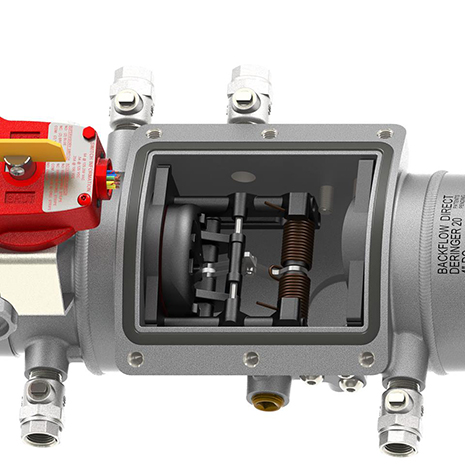

Dual-Action Check Swing Action and Poppet Action

The initial 25% of the opening stroke of the Dual-Action Check is that of a traditional "Poppet" action check with the following features: • Consistent static sealing and differentials |

|

|

The last 75% of the opening stroke of the Dual-Action Check is that of a traditional "Swing" action check providing the following features: • Minimal friction loss at high flow rates |

Tuesday, December 4, 2012

Dual-Action Check US Patent Filing

| Backflow Direct filed for US Patent: Dual-Action Check on December 4, 2012 |  |

Dual-Action™ Check module

The Patent Pending Dual-Action Check™ module is the core technology behind the superior performance of the Deringer Backflow Prevention Product Line. The Dual-Action Check™ combines all of the best features of industry standard “poppet” checks and “swing” checks creating a single high performance Dual-Action™ Check module.

|

|

Bow Seal Full Access Cover US Patent Filing

| Backflow Direct filed for US Patent: Bow-Seal™ Full Access Cover on December 4, 2012 |  |

Bow-Seal™ Full Access Cover

| The BACKFLOW DIRECT sales model requires direct shipment to it's customers via UPS/FedEx therefore our valves must be as small and light as physically possible. The Patent Pending Bow-Seal™ Full Access Cover accomplishes this and much more: • Light weight • Simple removal • No sliding seals • Full access to valve internals • No supplemental cumbersome and heavy couplings The Bow-Seal™ Full Access Cover is pre-formed to a partially cylindrical shape friendly to high fluid pressure. This allows the cover to be much thinner and lighter than traditional flat covers while still providing FULL access to internal valve components. |  |

|

|